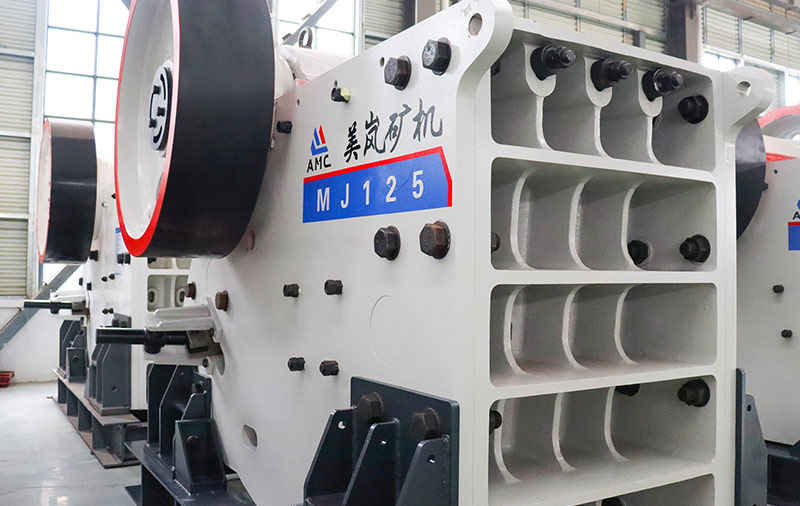

MJ series jaw crusher is mainly used as primary crusher. It is made of advanced technology in Europe and America and high-quality wear-resistant raw materials. The equipment has good performance, large crushing ratio and high output. It mainly deals with high strength and high hardness materials. It is the primary equipment of mine crushing production line and lays a good foundation for subsequent equipment. The design of this new type of jawbone structure is more scientific and reasonable, and the operation parameters, structural form, maintenance and adjustment of the equipment have more advantages than traditional machines.

Material: Granite, marble, basalt, limestone, quartzite, river pebble, iron ore, copper ore, etc

Application field: Sand and gravel yard, mining, coal mining, concrete mixing plant, cement processing and other fields.

| Model | Feed opening size (mm) |

Power (kw) |

Discharge size (mm) |

Weight (kg) |

||||||||||

| Crushing output | ||||||||||||||

| 40 | 60 | 80 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 300 | ||||

| MJ80 | 800*510 | 75 | 80-100 | 120-150 | 160-220 | 200-270 | 260-340 | 310-400 | 360-470 | 11800 | ||||

| MJ100 | 1000*750 | 110 | 210-280 | 270-350 | 320-420 | 390-510 | 460-600 | 520-680 | 26200 | |||||

| MJ125 | 1250*950 | 160 | 370-480 | 440-575 | 515-680 | 580-770 | 665--870 | 740-960 | 810-1060 | 44600 | ||||

| MJ140 | 1400*1070 | 200 | 480-630 | 575-745 | 660-850 | 750-960 | 830-1065 | 910-1190 | 58600 | |||||

| MJ160 | 1600*1200 | 250 | 640-840 | 750-980 | 850-1100 | 950-1200 | 1020-1330 | 1220-1600 | 85600 | |||||

| MJ200 | 2000*1500 | 400 | 960-1200 | 1060-1380 | 1170-1560 | 1280-1650 | 1520-1980 | 128500 | ||||||

Remarks: The output in the table is based on the approximate throughput measured by the loose density of the material at 1600KG/m3. The actual result will be different due to the difference in feed, particle size, rock type and material moisture content.